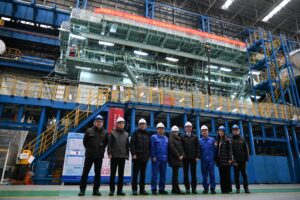

Matecs: Producing High Pressure Dredge Valves for DEME

Matecs BV, a Roosendaal based developer and producer of metal industrial parts for heavy duty usage, is currently producing high pressure (up to 40 bars) dredge valves for DEME’s newbuilding trailing suction hopper dredger Bonny River.

These valves have been equipped with wear-resistant liners and a specially developed guiding system for the gate.

“All Matecs valves are developed and manufactured entirely in house. Our standard product range can be adapted for use with different pressures or to incorporate various other options and features,” the company stated.

The valves for the trailing suction hopper dredgers Minerva and Scheldt River, also DEME’s vessels, were delivered a few months ago.

The Dual-Fuel Engines

The multifunctional dredging vessel, named the Bonny River, is the 15,000m³ TSHD and will be supplied with an extended suction pipe, and an additional suction pipe with heavy-duty rock draghead, enabling the vessel to operate in hard soil areas.

The dredger, being built by Royal IHC, will be the first vessel in DEME’s fleet with a closed process water circuit. This minimizes the turbidity generated by overflow water and enables the vessel to dredge in environmentally vulnerable areas.

The hydrodynamic hull and the dual-fuel engines (diesel and LNG) ensure further optimization of fuel consumption levels and a minimal CO2 footprint.

Due to its limited depth when loaded, the Bonny River is also suited to operations in shallow water.

[mappress mapid=”23132″]