Fehmarnbelt dredging hits halfway mark

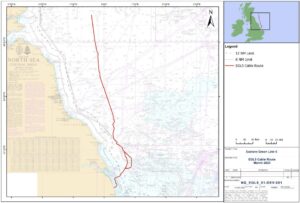

Dredging operations for the 18 km Fehmarnbelt tunnel between Denmark and Germany achieved a major milestone a couple of days ago – 50 pct of the total amount of soil has now been dredged from the seabed.

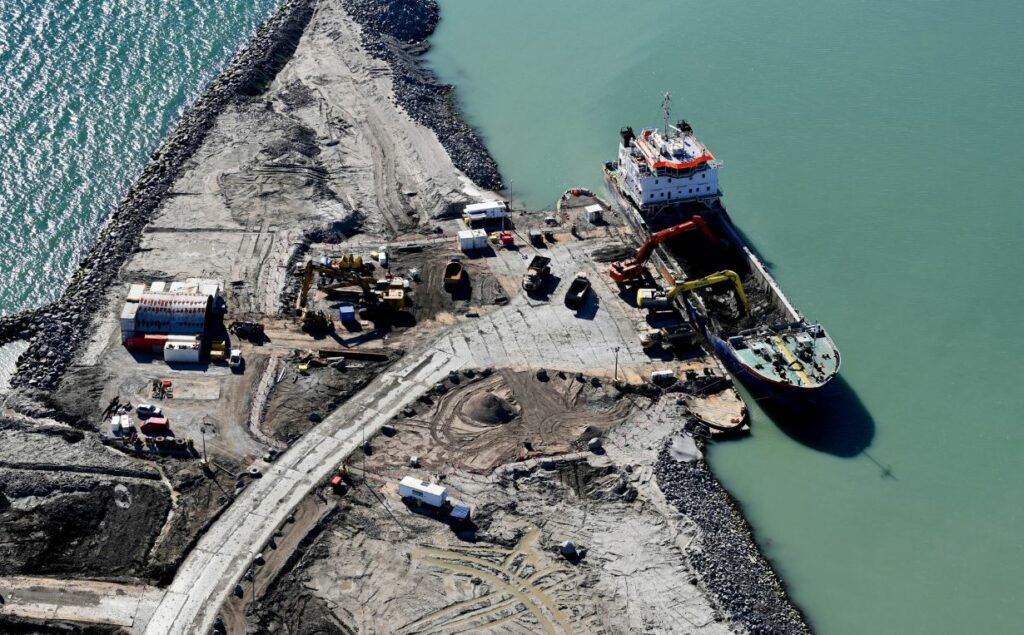

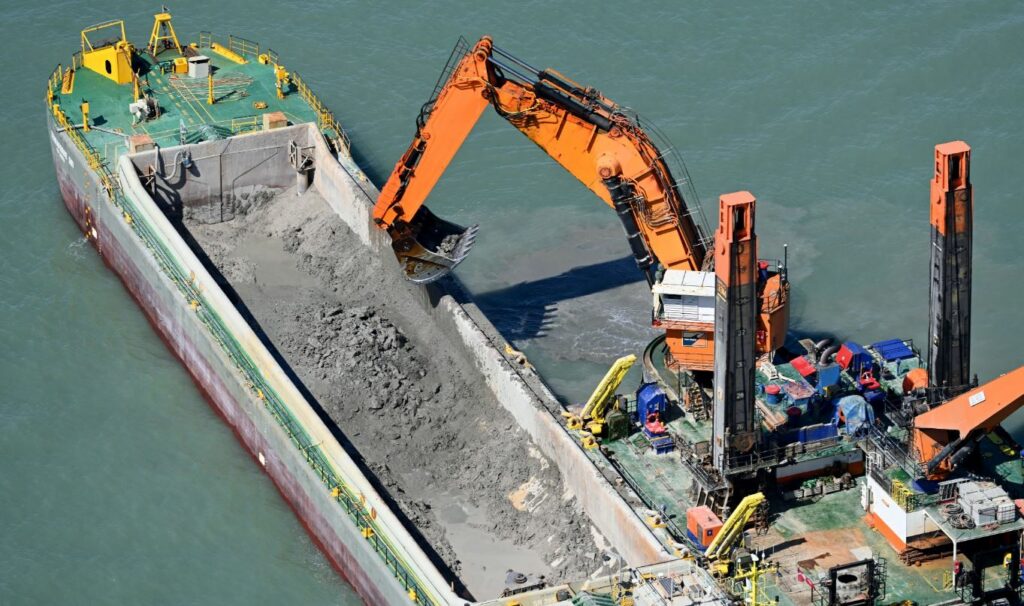

The Dutch consortium, Fehmarn Belt Contractors (FBC) including Boskalis and Van Oord – responsible for dredging part of the project, is using some of the world’s largest dredgers plus barges, tugs and other specialist vessels for this job.

Commenting the latest achievement, Bart Pröpper, FBC Project Director, said: “We’re proud to have achieved 50 pct of the dredging operations. This has been possible thanks to the expertise and dedication of the FBC team and our partners as well as the deployment of a number of specialised vessels and machines on land.“

According to Trine Bramsen, Denmark’s Minister of Transport, “The construction project is of great importance to the business community and for employment opportunities on Lolland and in the region.“

“The completed tunnel will also make a significant contribution to the green transition of the transport sector and provide a fast European train link. It’s to everyone’s benefit that the construction of the Fehmarnbelt tunnel is on schedule and that an important milestone has now been accomplished.”

According to the official plan, up to 19 million cubic metres will be dredged from the seabed.

Protecting the environment

The choice of dredging machinery not only relates to size but also ensures that the work can be carried out with due care for the surrounding marine environment.

FBC’s dredgers operate with great precision in the depths of the Fehmarnbelt, said Femern A/S – Danish planning company tasked with designing and planning of the tunnel.

The work is also performed as carefully as possible and the amount of spill from the dredged material is so far below the level agreed with the Danish and German authorities.

“We are, of course, delighted that the work is progressing on schedule. Our focus is now on the project’s next goal,” said Henrik Vincentsen, CEO, Femern A/S.

“For us, it is important that the construction of the Fehmarnbelt tunnel is built as sustainably as possible. Wherever possible, we and our contractors, try to identify opportunities to optimize the project for environmental reasons and to contribute our know-how for future infrastructure projects.”

Most of the dredged material will be reused east and west of Rødbyhavn and on Fehmarn on the German side to create new nature and recreational areas.

Four lane motorway

The Fehmarnbelt tunnel will comprise a four lane motorway and two electrified rail tracks.

The tunnel will consist of 79 individual elements, each 217 metres long, and 10 special elements with a lower floor for tunnel operations and maintenance equipment.

Once completed, it will take 10 minutes to travel from Denmark to Germany by car and 7 minutes by train.

This means that international trains and lorries passing through Denmark will be saved a 160 km detour, thus significantly reducing their CO2 emissions.

Also, the Fehmarnbelt link will be a major contributor to Europe’s future sustainable transport network by making it attractive to switch freight transport from road to rail.

CO2e neutral

Femern A/S’ objective for the operation of the Fehmarnbelt fixed link, which will open in 2029, is to be CO2e neutral.

This will be achieved through the deployment of energy-efficient solutions, the procurement of green energy for the operation of the link through green Power Purchase-Agreements (PPA) and by planting new forests that absorb CO2.

Femern A/S will achieve this ambition through three specific initiatives:

- Optimise energy efficiency in the operation of the link;

- Ensure 100% green energy for the operation of the link;

- Offset remaining emissions through afforestation.

Dredging operations for the Fehmarnbelt tunnel got underway in July 2021 and are expected to be completed in 2024.

According to FBC, this will be followed by the immersion of the first tunnel element.