China’s FPSO mooring system for deepwater oil & gas fields earns double blessing

The internal turret buoy single-point mooring system developed by China Offshore Oil Engineering Company (COOEC), controlled by China National Offshore Oil Corporation (CNOOC), has received two approvals in principle (AIP), one from the China Classification Society (CCC) and another from Bureau Veritas.

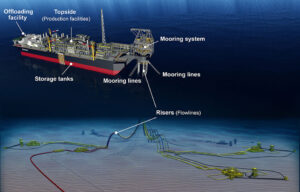

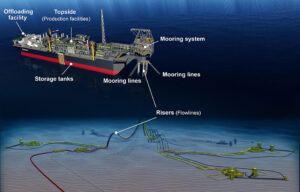

As the system is said to be the first of its kind in China, it is perceived as a breakthrough in the country’s research and development capabilities for deepwater oil and gas equipment, contributing to the economic development of its deepwater fields. The single-point mooring system enables floating production, storage, and offloading (FPSO) units to maintain stable production operations at sea by acting as a weather vane, assisting in vessel positioning.

Under the influence of wind, waves, and currents, the FPSO device rotates around the single-point mooring system, making it less susceptible to external forces. At the same time, the system can be used for electricity and communication transmission, as well as transporting fluids.

According to the Chinese player, the quick-release function enables the inner turret single-point mooring system to withstand even a strong typhoon. With a design life of over 20 years, it is suitable for water depths of up to 500 meters. A buoy has been operating for over 300 days on the FPSO Nanhai Endeavour in Huizhou oilfield, ensuring its production and operation.

COOEC says that its projects in recent years encompassed building multiple floating production facilities, including what it deems is the world’s first 100,000-ton semi-submersible production and storage platform at Deep Sea No. 1, Asia’s first cylindrical FPSO unit Anemone No. 1, and the country’s largest operating water depth FPSO unit Marine Oil 119.

In the future, the firm plans to focus its efforts on technological research and development required to upgrade the upstream and downstream industrial chains, as well as on enhancing the deepwater oil and gas equipment industry chain by improving its design, product manufacturing, final assembly and integration, and engineering application capabilities.

In May, COOEC picked ABL to provide marine warranty survey (MWS) services for jacket installations on the Aramco-operated Safaniya oil field, which is said to be the world’s biggest conventional offshore oil field in terms of both recoverable reserves and production capacity.