WinGD rolls out on-engine emissions solution to simplify decarbonisation for ship operators

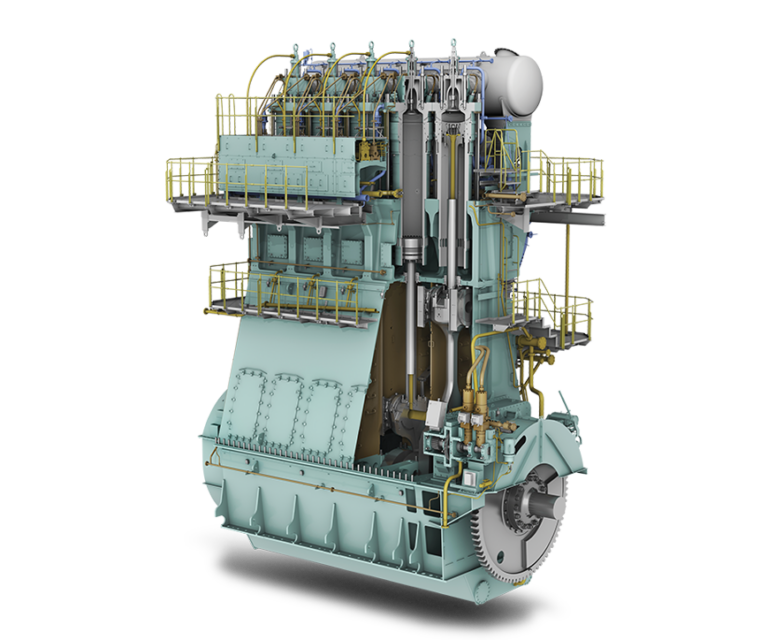

Swiss marine power company WinGD has introduced an on-engine version of its Intelligent Control by Exhaust Recycling (iCER) system as part of its commitment to making decarbonisation as simple as possible for ship operators.

According to WinGD, the new version enables the emissions reduction technology to be installed without impact on engine footprint.

The principle behind iCER is to minimise emissions by regulating air and exhaust gas flow. By cooling and recirculating exhaust back to the engine, more gases which can contribute to climate change are combusted without escaping into the atmosphere.

iCER is the first X-DF2.0 technology launched to enhance the emissions performance and efficiency of the widely deployed dual-fuel X-DF two-stroke engine series.

Related Article

X-DF engines running on liquefied natural gas (LNG) are said to offer a more than 20% reduction in greenhouse gas (GHG) emissions and a dramatic reduction in air pollution compared to fuel oil.

The addition of iCER delivers a 50% reduction of methane slip in gas mode. Combined with better fuel efficiency, this reduces total GHG emissions by up to 8% in gas mode. Running on diesel, iCER improves the emissions performance of X-DF engines by 6%, the developer claims.

Now, the on-engine iCER offers the same advantages while simplifying testing, building and installation of the engine, as well as reducing the engine room space needed for emissions reduction equipment.

The exhaust gas cooler and all exhaust gas flow control components are installed on the engine, offering significant engine room design flexibility, WinGD explained.

As disclosed, on-engine iCER is initially available on WinGD’s X72DF engines and will be rolled out to other models in the X-DF engine range.

“In addition to reducing methane slip and total GHG emissions, both on- and off-engine iCER enable compliance with IMO’s Tier III NOx limits, whether using LNG or diesel fuels”, WinGD said.

According to Rudolf Holtbecker, executive director of Operations at WinGD, this addition to the choices in the company’s X-DF2.0 portfolio extends the benefits to all shipyards and global engine builders with an improved arrangement and a production-friendly design for minimised manufacturing and installation costs.